We can’t ignore embodied carbon in buildings any longer, here's why...

Photo by Robert Bye on Unsplash

Michelle Sanchez, Project Designer at PDP London and contributor to the new London Energy Transformation Initiative (LETI) guides on carbon alignment, makes a compelling argument for our need to address embodied carbon.

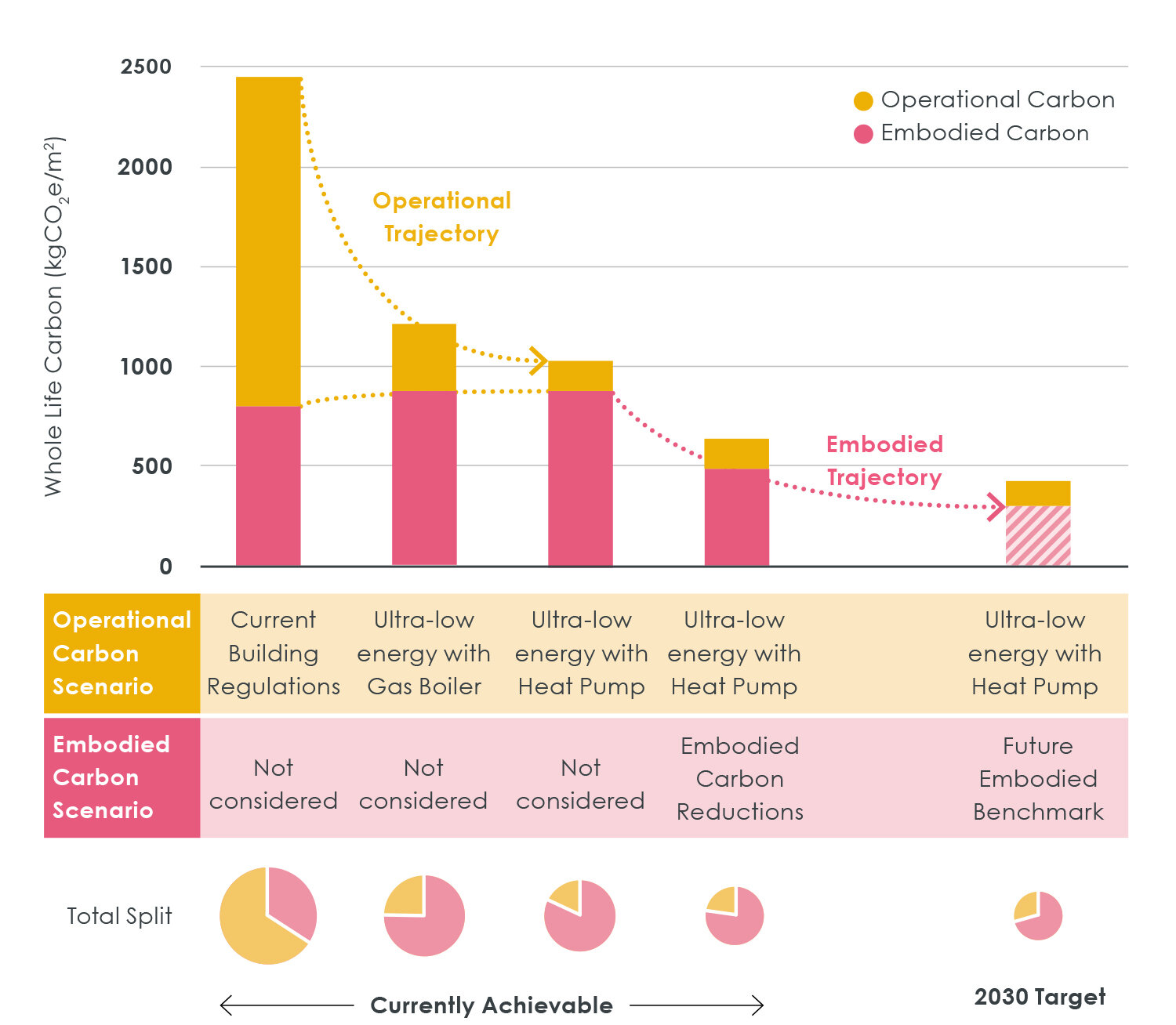

If we look at whole life carbon in the context of progress over the past decades we can see why we now need to prioritise our efforts on embodied carbon if we are to meet our 2030 targets.

To start talking about embodied carbon we must first explain what it is and why it is important to any building design progress. Embodied carbon refers to the carbon emissions emitted whilst producing a building’s materials, their transport and installation on site as well as their disposal at end of life.

The current regulations and sustainable certifications are mainly focused on reducing operational carbon, and not embodied carbon. The construction industry has been focusing so much on reducing the operational carbon in the last 50+ years because, if you analysed the life cycle of a building, operational carbon would be around 60% of the total emissions throughout a building’s life span.

The efforts that the industry has implemented to reduce operational carbon has allowed us to shift this percentage and that is why we are now starting to think about ways of reducing embodied carbon. If you analyse the overall environmental footprint of a building over its life cycle you will see that embodied carbon is now a major component of that footprint.

Diagram showing operational and embodied carbon and trajectories

Source: LETI Embodied Carbon Primer

We now believe that to truly achieve Net Zero Carbon by 2030 we have to be focused, not only on reducing the operational carbon, but also the embodied carbon. We need to analyse the whole life cycle of a building from production of raw materials (A1) until deconstruction and demolition (C1).

As architects, we have a major role to play in this. We need to take into consideration the whole environmental impact and start thinking of buildings, not only until the end of construction, but also during their entire life. We need to take responsibility for its impact and have strategies in place to make sure that our designs, in reality, function exactly the way they were intended to.

System Boundary: EN 15978:2011 Display of modular information for the different stages of the building assessment

Source: LETI Embodied Carbon Primer

Current building regulations do not include the analysis and reduction of embodied carbon. The new London Plan includes the requirement for a Life Cycle Assessment to be taken at RIBA Stage 2, 4 and 6 (GLA Policy SI 2); the policy does not include targets to reduce embodied carbon, because the GLA is currently analysing different targets to make sure that what is included into the policy is based on a reliable goal.

Even though this policy currently only applies to planning applications which are referred to the Mayor of London, the GLA is encouraging London councils to include this policy in their planning policy to make sure that, in the near future, all projects will be required to deliver a Life Cycle Assessment and an embodied carbon reduction.

Approach to operational carbon, to deliver zero carbon buildings.

Source: LETI Net Zero One Pager

Road Map to implementation, how will this affect the design process of a building?

Stage 0 – Discuss Whole Life Carbon Ambitions with the client, explain the key points, set targets. Review opportunities for refurbishment and retrofitting the existing structure.

Stage 1 – Develop a client brief that incorporates embodied carbon reduction targets. Appoint an LCA consultant.

Stage 2 – Run the first LCA and analyse carbon reductions options for building elements.

Stage 3 – Include requirements and targets in tender documentation, have discussions with the potential main contractor about the requirements. An LCA can be run to adjust the design.

Stage 4 – Finalise all the requirements and targets and include everything in the tender documentation. Final discussions with main contractor and sub-contractor about targets and requirements, asking for options for improvement (Environmental Product Declaration (EPD) and adding carbon questions on tender returns forms). Run an LCA before issuing the tender information.

Stage 5 – Analyse any construction changes against the carbon reduction requirements.

Stage 6 – Undertake post completion LCA.

Stage 7 – Run an LCA every 5 years, analyse any maintenance or replacement works.

RIBA Stages actions for the designer and LCA specialist

Source: LETI Embodied Carbon Primer

At PDP London we believe a real zero carbon building should take into consideration not only the operational carbon, but also the embodied carbon during the whole life cycle of the building. To be able to provide this level of detail in our designs, we are actively improving the knowledge levels of all our architects to make sure that we can provide the best advice and design for our clients. We’re also delivering CPDs to consultants, clients and potential clients regarding different sustainability subjects to make sure that we elevate the knowledge level of the industry as a whole.

Michelle Sanchez has contributed to the new LETI Climate Emergency Design Guide, LETI Embodied Carbon Primer, recently published one-pagers as part of LETI’s carbon alignment and the CIBSE publication, Embodied carbon in building services: A calculation methodology (TM65). She is currently on maternity leave, but if you would like more information please contact Marion Baeli.